-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- Cell 2025

- ASIA LABEX: The Lab Show 2025

-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- Cell 2025

- ASIA LABEX: The Lab Show 2025

-

- All Pipettes, Dispensers & Automated Liquid Handlers

- Mechanical Pipettes

- Electronic Pipettes

- Multi-Channel Pipettes

- Positive Displacement Pipettes & Dispensers

- Automated Pipetting

- Bottle-Top Dispensers

- Pipette Controllers

- Pipette Tips

- Automation Consumables

- Dispenser & Pipette Accessories

- Automation Accessories

- Dispenser & Pipette Services

You are about to leave this site.

Please be aware that your current cart is not saved yet and cannot be restored on the new site nor when you come back. If you want to save your cart please login in into your account.

Freezer Service

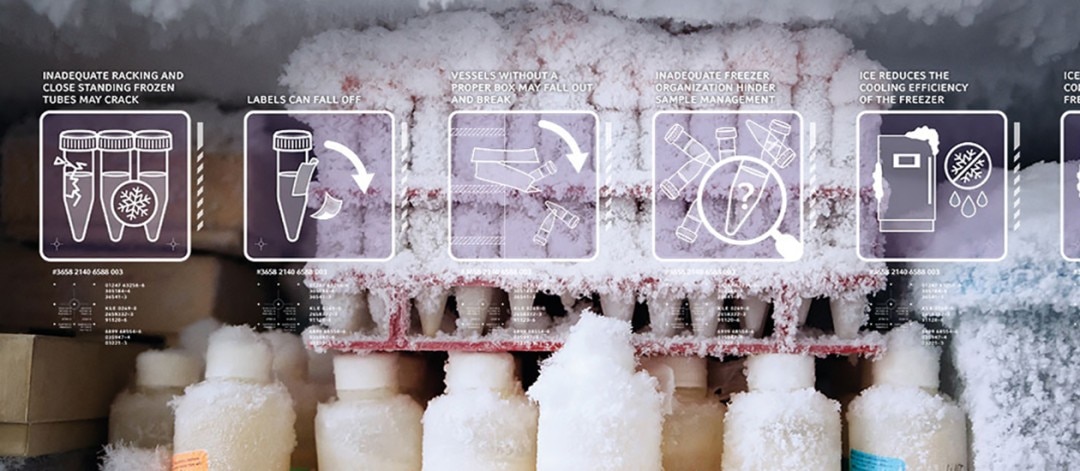

Protect your priceless samples!

Eppendorf Ultra-Low Temperature (ULT) Freezers offer you the advanced design and intuitive features you like on the outside plus the security and performance you need for your most precious samples on the inside. Reliable and efficient performance can be expected for years of smooth operation from any of our ULT Freezers, which vary in configuration and capacity. Eppendorf offers ULT Freezer preventive maintenance services to suit your lab’s needs and to avoid unexpected freezer repair services while enhancing your peace of mind.

You can choose between essential function checks, preventive maintenance plans, or Installation and Operational (IQ/OQ) certification services including temperature verification services. These protocols are designed to check, validate, and promote reliable freezer performance that coincide with our manufacturer specifications.

Preventive Maintenance

Global ULT Freezer Service Agreements from cost-efficient to all-inclusive care packages for easier service process, maximized uptime, and peace of mind!

Our new comprehensive service agreements

- "AdvancedCare" includes a full annual preventive maintenance service program for assured instrument reliability and uptime; 20 % discount on parts, labor and travel; 10 % discount on additional services (e.g. IQ/OQ) during the agreement period

- "PremiumCare" includes a full annual preventive maintenance service program for assured instrument reliability and uptime; unlimited travel, spare parts and labor on repairs included in the agreement; 10 % discount on additional services (e.g. IQ/OQ) during the agreement period

Our preventive maintenance only services

- "Preventive Maintenance" includes all preventive maintenance services to keep the instrument in accordance with the manufacturer specifications

Qualification Services

ULT Freezer Service Agreements

| Service Agreement Ordering Information | AdvancedCare For assured instrument reliability and uptime | PremiumCare For assured instrument reliability, uptime and financial plannability |

| ULT Freezer | ||

| Includes: | ||

| Full preventive maintenance | 1/year | 1/year |

| Software update (during annual maintenance, if applicable) | ||

| Priority Support* | ||

| Discount on parts, labor, travel | 20 % | included |

| Parts, labor & travel included | - | |

| Discount on additional services (e.g. IQ/OQ) | 10 % | 10 % |

Info: Our service offers may differ by country. Please contact your local service representative for more information.

*Subject to local business conditions, and based on a best effort’ practise. For more information please contact your local service organization

ULT Freezer Preventive Maintenance Services

| Preventive Maintenance Ordering information | Preventive Maintenance |

| ULT Freezer | |

| External Checks and Maintenance | |

| Check installation environment | |

| Check electrical supply and fittings | |

| Check CO2 /LN2 backup system installation* | |

| Check independent temperature monitoring system* | |

| Operation of freezer lid gas strut (chest freezer only) | |

| Alignment of door handle | |

| Alignment and sealing of outer door (upright freezer only) | |

| Air filter inspection and cleaning | |

| Internal Equipment and Fittings | |

| Inspection and cleaning of heated vent/condensor | |

| Condition and function of inner doors/lids | |

| Compressors: operating temperature check | |

| Cooling fan: condition of fan motor, bearings, fan blades | |

| Condition of insulation – accessible cooling circuit pipes | |

| Condition of accessible electrical wiring | |

| Display and function keys operation | |

| Chamber temperature sensor function, alarms function | |

| RS232/RS485 communications port functionality check | |

| Validation and Metrology | |

| Validation and adjustment of operating parameters to within Eppendorf specifications | |

| Documentation | |

| Check List provided | |

| Dated service sticker to confirm Eppendorf service |